Our FA consulting servie is that it is required durarency, availability and Maintainability when a customer considers to introduce the new inspection equipment on which the mass production plant is required 24 hours 365 days operation. Even such a circumstance we are able to support to introduce or any update the equipment step by step.

Many kind of the image peocessing inspection devices have been using in the automotive manufucture plant for their quarity control. However most of case, its maintence is very complecate and keeping its detection accuracy is also very difficult. it is differ from mechanical device maintenance. It is a worries that ometimes it is needed optical knowledges, too. We are able to give a way to solve the challenge with our know-how.

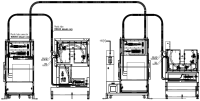

It consists of a control panel that houses an image processing PC and a switchboard, and a sensor rack that includes a camera, lighting equipment, and various sensors. The control panel is an iPro original product.

Since 3D CAD editing is performed in the eye pro, the internal configuration and size can be changed finely and freely according to the customer's request. Not only in Japan but also in North America, we have a track record of shipping, so we can support global standards.

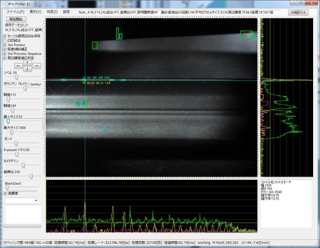

IPro's original surface inspection software is implemented on a tablet PC running Windows 7 or later. All you have to do is connect a USB camera. Since OpenCV is used for the image processing library, there is no need for expensive runtime license fees for the image processing library. The following functions are implemented.

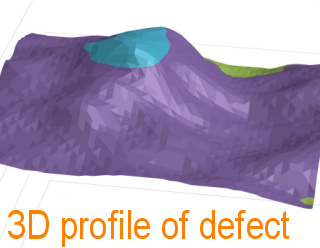

Getting the appropriate defect detection needs to know how is the property of target defect and it needs to know difference a normal and abnormal surface through the analyzing such as brightness level profile difference, to make a threshold value of the image processing. Converted image data to the CSV file will be able to read by Microsoft Excel and draw the 3D graph for visualize the defect shape, that is implemented our inspection software as one of the function.

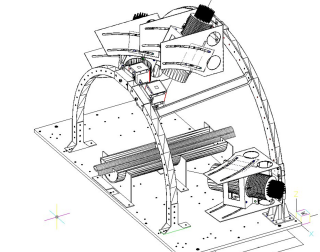

We manufacture in-house lighting equipment that is indispensable for image processing equipment. Depending on the target, we will evaluate the camera, lighting layout, and lighting type through evaluation, and if it is difficult to handle with commercial image processing lighting, we also design and manufacture a dedicated lighting device. The figure on the right is a 3D CAD design drawing of the evaluation device created for the lighting device evaluation.

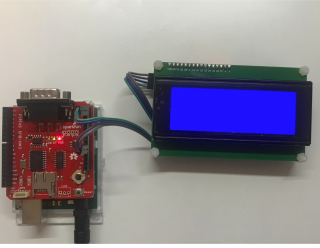

The picture on right is iPro CAN logger which is implemented a 16x4 character LCD display with blue backlight, a CAN controller onto the Arduino as main processing unit. It can be connected to vehicles DLC connector easily and price of it is very affordable. This iPro CAN device weaks for high speed acquisition due to processor performance however once you decided CAN-ID filters it works well, for an affordable price. it dosen't need to concern a heat problem too. Since this is a basic hardware, you need to make or addition a program according to your requirement. We can provide and modify the program to what you want.